Today, the manufacturing world is characterized by the apparent existence of a similar alternative to every product. The problem is not simply producing a good sponge for sanding, it’s also producing a popular sponge for sanding. Whether you’re a manufacturer, a wholesaler, or a brand owner, you already know that the difference between a “good product” and a ” leading brand” is often lost in the finer details, including the formulation of the product, the packaging, or the psychology of customers.

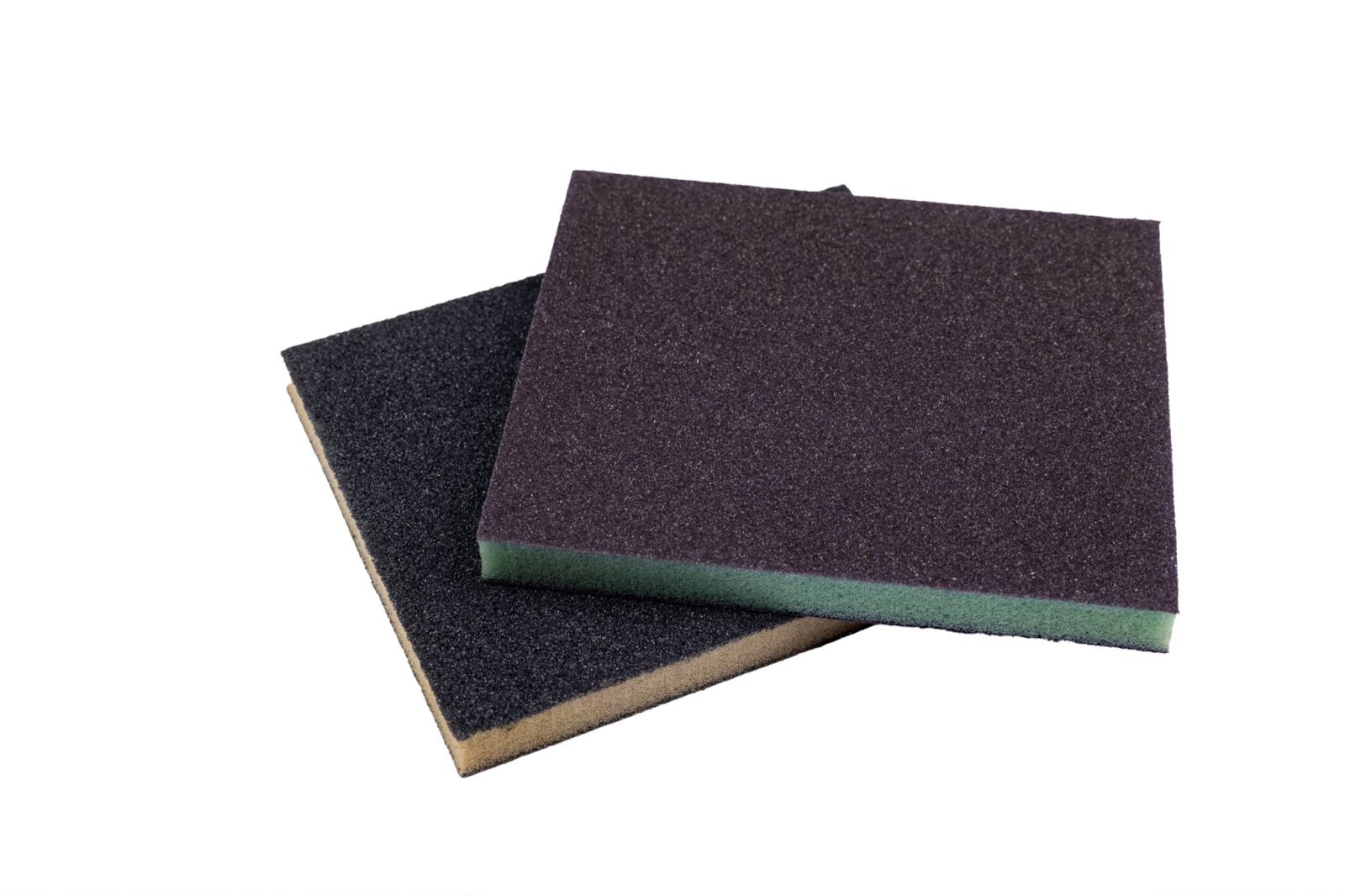

The sponge that sands is simple to understand, but it achieves a balance between craftsmanship and efficiency. It’s now become an essential tool for both professionals and hobbyists, including carpenters who smooth the wood panels or automotive painters who perfect the details. However, in a competitive market, how does one become the fastest, most popular, and most dedicated seller?

This article combines practical knowledge with firsthand experience, demonstrating how smart engineering, scientific research, marketing expertise, and narrative power can augment a basic tool into a popular product that draws in both business-to-business and business-to-consumer applications.

What Makes a Sanding Sponge “Hot Sale”

Before diving into production strategies, we need to define what “hot sale” really means in the context of sanding tools. It’s not just about sales numbers. A hot-selling Sanding Sponge achieves three things:

-

It solves real user pain points better than competitors.

Users return to a product that makes their work easier, lasts longer, and feels better in the hand. -

It has visual and tactile appeal.

Texture, color, grit labeling, and ergonomic design affect purchasing decisions more than most realize. -

It is backed by strong distribution, reliability, and word of mouth.

The best-selling tools aren’t always the cheapest — they’re the ones users trust to perform consistently.

The secret lies in combining engineering precision with market awareness. Every “hot sale” success starts in the factory but wins its reputation in the marketplace.

The Foundation of Every Hot Sale Sanding Sponge

One major mistake manufacturers make is assuming that all sanding sponge buyers are the same. In reality, the market divides into distinct user profiles — each with different expectations, willingness to pay, and product priorities.

| User Type | Core Needs | Buying Behavior |

|---|---|---|

| Professional Contractors | Durability, consistent grit performance, and easy cleaning | Buy in bulk, prefer proven brands |

| Automotive Refinishing Technicians | Fine finishing, water-resistance, reusability | Choose high-grit or flexible edge models |

| DIY Hobbyists | Affordable, easy to use, versatile | Influenced by visuals, reviews, and availability |

| Retailers / Distributors | Stable supply, private label options | Require strong packaging and shipping reliability |

If you want to create a hot sale Sanding Sponge, you must understand how these segments think and buy. A product that meets the ergonomic needs of a carpenter might not satisfy an auto refinisher. Knowing your end users deeply allows you to design and position your product effectively.

Designing the Ideal Sanding Sponge: Function Meets Form

Every buyer starts by touching the product. Whether in a store or online, the first impression matters. The physical design of your sanding sponge can directly impact its perceived quality.

Think of the hot-selling Sanding Sponge as a balance between three elements: material innovation, surface engineering, and user experience.

Material Innovation

High-quality foam is the core of a sanding sponge. Today, manufacturers employ closed-cell polyurethane foam for its water-resisting properties, and open-cell variants for increased flexibility. The proper amount of foam is the one that distributes pressure most evenly across the surface; too soft, and it will wear quickly; too hard, and it will leave scratches.

Premium producers often employ anti-worming coatings that prevent dust accumulation. Others utilize water-resistant adhesive that allows the sponge to function in both wet and dry conditions.

Surface Engineering

A block with a uniform amount of grit that adheres to the foam ensures a consistent abrasion. Uneven coating has inconsistent results, which professionals are easily aware of. Using advanced electrostatic coating methods that are specific to the grain’s shape ensures that each abrasive particle is positioned correctly, which improves the consistency of performance and the lifespan of the product.

User Experience

Shape, weight, and flexibility matter. Rounded edges prevent gouging delicate surfaces. Color-coded grits (e.g., blue for medium, grey for fine) help users quickly identify tools. Ergonomic contouring enhances comfort, particularly for prolonged sanding sessions.

The Key Features That Make a Sanding Sponge a Bestseller

To transform a regular sanding sponge into a “hot sale” product, focus on key functional differentiators:

-

Durability and Grit Retention: High-grade aluminum oxide or silicon carbide ensures longevity.

-

Flexibility and Form Recovery: Foam that returns to its shape after pressure maintains performance over time.

-

Multi-Purpose Compatibility: Usable on wood, metal, plastic, drywall, and paint — appealing to more users.

-

Wet and Dry Application: Expands usability for auto refinishing, marine finishing, and woodworking.

-

Anti-Clogging and Washable: Extends lifespan and enhances cleaning ease.

These features don’t just add value — they justify a higher price point and make marketing easier. When a user says, “This sponge lasts longer,” you’re halfway to becoming a “hot sale” brand.

Material Science and the Technology Behind It

Let’s get more technical. The success of a hot sale Sanding Sponge often starts at the molecular level — with the interaction between foam and abrasive particles.

Here’s a comparative overview:

| Aspect | Traditional Sponge | High-Performance Sanding Sponge |

|---|---|---|

| Foam Density | Low-density open cell | Optimized mixed-cell with rebound effect |

| Adhesive Type | Generic glue | Heat-resistant water-based bonding |

| Abrasive Material | Basic silicon carbide | Treated aluminum oxide or ceramic oxide |

| Durability | 2–3 usage cycles | 6–8 usage cycles |

| Surface Consistency | Uneven grit spread | Precision-coated micro-layer |

The secret to developing a professional sanding tool is in precise coating and controlled burning. The temperature of the adhesive must correspond with the foam’s expansion coefficient; otherwise, early delamination is likely.

Modern factories employ automated systems for coating abrasives and infrared-based production to ensure consistent production. Investing in this level of precision results in sanding sponges that are both popular and long-lasting.

Quality Control: The Backbone of Market Trust

Every hot-selling Sanding Sponge brand earns its reputation through consistency. Quality control ensures that every sponge leaving the factory performs exactly as promised.

Here’s where many small factories fail — they focus only on final inspection. But a professional custom sanding sponge manufacturer builds quality assurance at every stage:

-

Foam inspection (density, elasticity, thickness)

-

Abrasive bonding adhesion test

-

Moisture and temperature curing records

-

Visual grit uniformity check

-

Randomized durability testing (manual and machine)

This systematic approach eliminates defects before packaging, reducing customer complaints and return rates — the silent killers of brand growth.

Branding and Packaging: Turning a Tool into a Statement

Your sanding sponge might be technically excellent, but if your packaging looks outdated or generic, it won’t sell. Buyers — especially in the retail and online markets — judge professionalism by how you present your product.

Smart brands apply color psychology and information clarity to packaging design:

-

Use bold color blocks to signify grit level.

-

Add clear icons: “wet/dry use,” “washable,” “multi-surface.”

-

Show before/after images to illustrate the effect.

-

Include eco-friendly claims if applicable — it matters.

Packaging isn’t just an afterthought; it’s part of the value proposition. Many successful hot-selling Sanding Sponge brands rebranded old stock with premium packaging and saw immediate sales jumps.

Marketing Strategy for a Hot Sale Sanding Sponge

In today’s market, the right marketing plan is as crucial as product quality. Here are effective strategies manufacturers use to boost sales:

-

SEO and Digital Presence

Create product listings optimized with keywords like hot sale Sanding Sponge, foam sanding block, and abrasive sponge pad. Include detailed descriptions, application photos, and usage videos. -

B2B Platforms and Trade Shows

Showcase your sponge at industry fairs (Canton Fair, Hardware Expo, etc.) and online platforms such as Alibaba and Made-in-China. Provide OEM/ODM options to attract bulk buyers. -

Video Demonstrations and Influencer Collaborations

Visual proof sells. Short, authentic videos showing sanding results outperform text-heavy ads. -

Customer Education

Publish maintenance tips and grit guides — helping buyers get better results makes them return. -

Loyalty and Distributor Programs

Encourage repeat purchases through bulk discounts, private labeling, or regional exclusivity.

Marketing isn’t about shouting louder — it’s about making sure your voice reaches the right ears with credibility and consistency.

Efficient Distribution and Logistics Management

A hot-selling Sanding Sponge isn’t just about demand — it’s about delivery. Many manufacturers lose sales not because of poor quality, but because of inconsistent logistics.

To stay competitive, you need:

-

Short production lead times with flexible MOQs.

-

Multiple shipping options (sea, air, express) for different buyer profiles.

-

Inventory tracking systems to prevent stock-outs.

-

Localized warehousing to improve responsiveness in key markets.

Fast and reliable delivery builds trust — and trust builds long-term orders.

The Modern Edge in Manufacturing

Environmental consciousness has reshaped consumer behavior across industries — even in hardware and abrasive tools.

Manufacturers focusing on eco-friendly foam, recyclable packaging, and non-toxic adhesives stand out. A sustainable hot sale Sanding Sponge doesn’t just appeal to environmentally conscious buyers — it positions the brand as forward-thinking.

Examples of sustainability practices:

-

Using water-based resins instead of solvent-based glue

-

Reducing foam trimming waste through precise cutting

-

Introducing biodegradable wrap packaging

Sustainability isn’t a marketing gimmick anymore; it’s a requirement for global relevance.

Customer Feedback and Continuous Improvement

A product that becomes a hot sale once can fade just as quickly — unless you evolve. The best brands integrate feedback into their R&D cycle.

Here’s how:

-

Collect user data through QR-coded feedback forms on packaging.

-

Analyze return reasons — quality issue or misinformation?

-

Adjust grit labeling or sponge density according to buyer usage.

-

Update visuals and tutorials periodically to match customer trends.

This loop ensures your product never stagnates and continues adapting to market expectations.

From Factory Floor to International Bestseller

Let’s take a practical example that is small in scale – a Chinese-based abrasive manufacturing company that produces generic blocks for the local market. The sales were small until management decided to reposition the product line around the popular Sanding Sponge strategy.

They began by augmenting materials with higher-density foam, standardizing the grit level, and redesigning the packaging with easily recognizable color codes. Next, they collaborated with online retailers and released a few videos; these videos demonstrated how their sponge was superior to others.

Within six months, the volume of exported goods increased by tripling. What altered was not luck, but rather the alignment of product quality, brand reputation, and marketing communication.

The same methodology is employed across the globe. If your sanding sponge is more effective and communicates more clearly, you not only create a product but also a brand narrative.

The Future of Sanding Sponge Manufacturing

The future is dedicated to innovation and personalization. The following wave of successful hot sales will come from factories that automate, have smart quality detection, and have even implemented AI-based performance testing.

Imagine manufacturing lines that use cameras to scan each sponge for the uniformity of grit in real time or a system that predicts the time of cure based on the humidity level. These are no longer futuristic fantasies — many advanced manufacturers have already incorporated these technologies.

Also, customization will have a significant influence on the market: branded flourishes, ergonomic grips, and sponge shapes that are tailored to specific applications (like the sanding of guitars or the 3D printing of surface features). The objective is simple: to have high precision, high performance, and personalized care.

Building a Lasting “Hot Sale” Legacy

A successful hot sale Sponge for sanding doesn’t occur all at once. It’s constructed through consistent spending on quality, market analysis, and a narrative that satisfies users.

In a competitive world, the most popular products are those that feel human: they are designed with sympathy, precision, and pride. Every sponge that sands at your plant carries the name of your brand’s advertisement. When that pledge is realized as to providing reliability, comfort, and demonstrable results, your sponge will no longer be considered just another tool. It will be the preferred choice.

This is the actual definition of a hot sale: when your product no longer seeks to attract customers, but instead seeks to satisfy them.