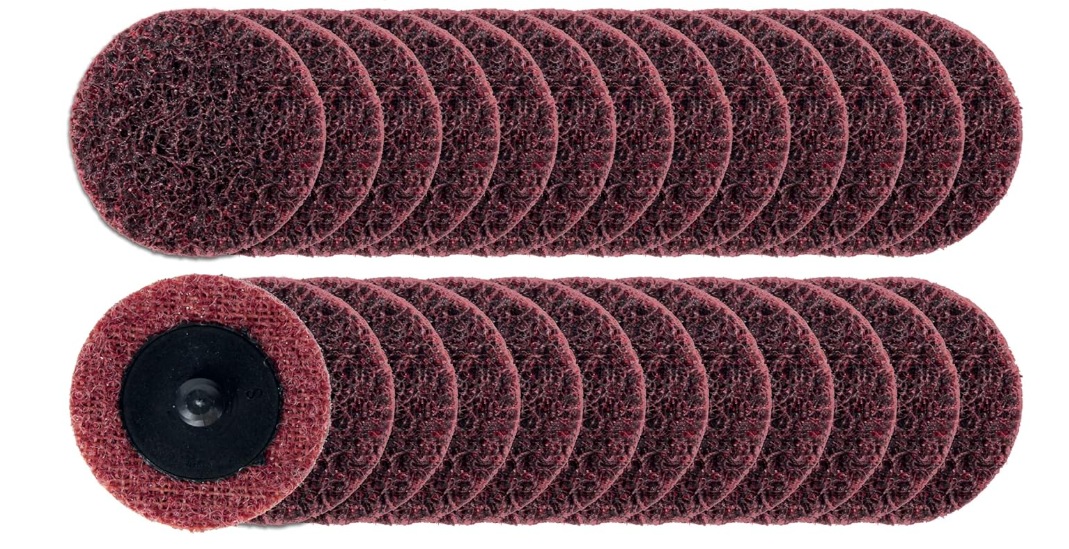

Surface conditioning disc are high-performance grinding tools specially designed for industrial surface treatment. Their unique structure integrates advanced materials and innovative processes, aiming to provide efficient, precise and long-lasting grinding solutions for the processing of various metals and some non-metal materials. Whether it is deburring, rust removal, weld seam treatment or surface finishing, nylon sand discs demonstrate outstanding adaptability and reliability, becoming indispensable assistants in numerous fields such as mechanical manufacturing, metal processing, aerospace, etc.

Core material:

High-strength nylon fibers are used as the base material. These fibers have excellent flexibility and wear resistance, maintaining structural stability during high-speed rotation and high-pressure grinding. They effectively buffer the impact force during grinding and prevent excessive damage to the workpiece surface. Meanwhile, nylon fibers can also closely bond with abrasive particles, ensuring that the abrasive does not easily fall off during operation and extending the service life of the abrasive disc.

In terms of abrasives, high-quality silicon carbide, alumina and other mineral sands are selected.These abrasives have been carefully selected and processed, featuring regular particle shapes, high hardness and strong cutting force. For instance, silicon carbide abrasives are particularly suitable for grinding metals with high hardness, such as alloy steel and stainless steel, and can quickly remove surface impurities and defects. Alumina abrasives perform exceptionally well when dealing with relatively soft metals such as aluminum and copper. They not only ensure efficient cutting but also produce smooth and fine surfaces after processing. Unique structure: The structural design of the nylon sand disc is ingeniously crafted

Surface Conditioning Disc have outstanding performance in metal surface pretreatment, coating removal and fine processing. The non-woven fabric nylon grinding disc, thanks to its conformable structure, is undoubtedly a revolutionary metal processing polishing tool, capable of handling a wide range of precision processing tasks, which leaves other surface treatment products (such as louver discs) far behind.

Unique structure:

The structural design of the nylon sand disc is ingenious, presenting an open three-dimensional mesh structure. The nylon fibers interweave with each other to form a spring-like mesh frame, with abrasive particles evenly distributed and firmly embedded in it. This structure enables the grinding disc to continuously expose new abrasive particles from the inside as the abrasive gradually wears out during operation, maintaining highly efficient cutting performance and achieving long-term stable grinding results. It avoids the problems of reduced grinding efficiency and inconsistent surface quality caused by abrasive consumption.

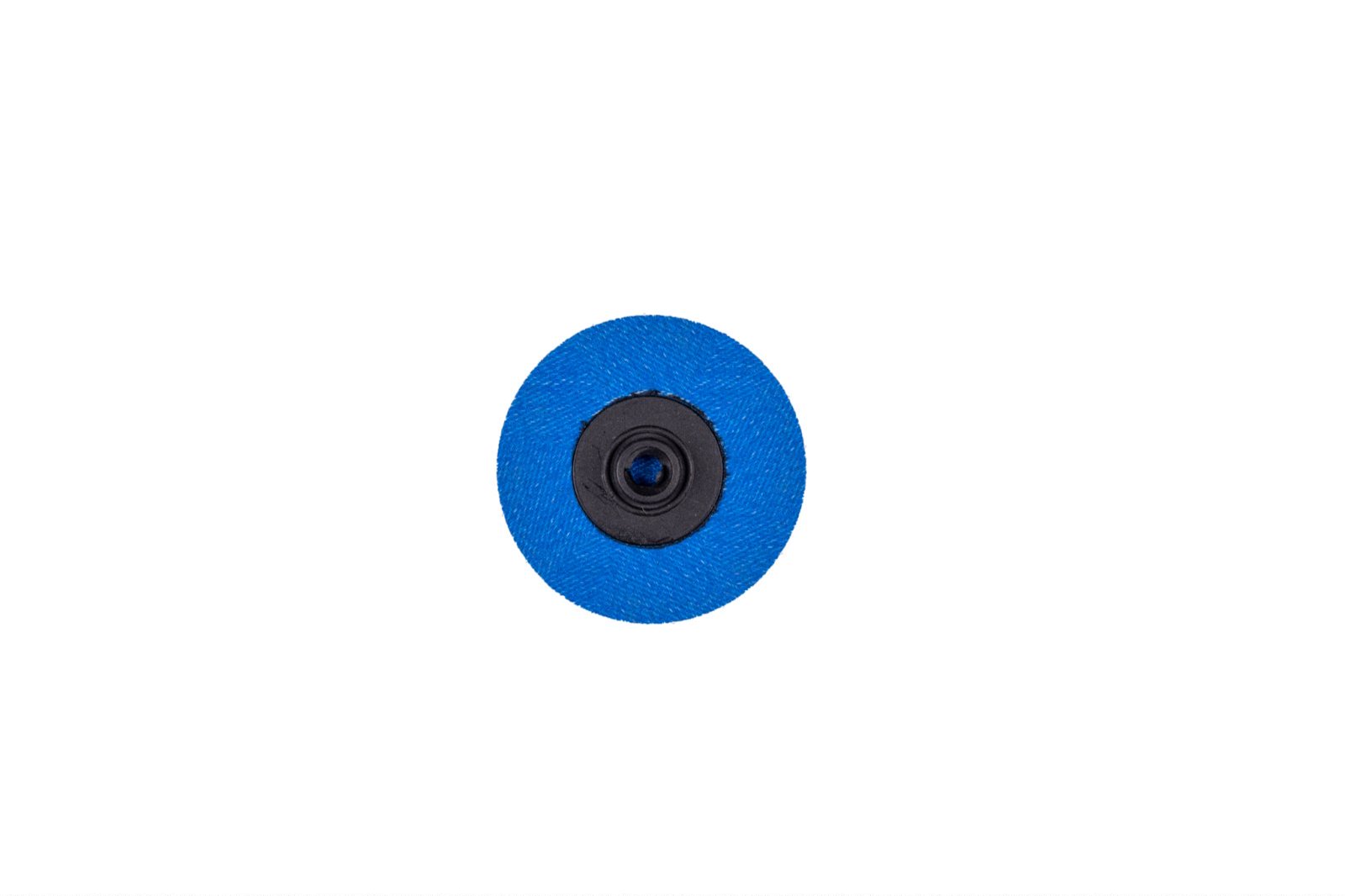

This product is a quick and efficient grinding tool used for deburring, processing of various metals. It is a quick changing device which can shorten the abrasive disk’s outage time.

- High Quality:Superior in performance with good durability, plasticity and flexibility, high abrasion resistance and fast grinding force

- Wide Application:For cleaning and finishing on all metals, for removal of light rust, oxides and coatings;Wide application to stainless steel, standard or alloyed steel, non-ferrous materials and alloys, plastic and fiberglass, for cleaning, finishing, blending and deburring applications

Nylon sand disc is mainly used for grinding and polishing welding seams, flat surface. The sheet metal coating of metal machining, such as automobile, motorcycle, metal stamping, die-casting die casting parts, instruments and meters, bicycle parts, textile machinery, medical equipment parts, tools, cutting tools, plumbing equipment, stainless steel tableware, stainless steel plate, golf head, electric vacuum device and other products of thefamily, deburring, round and mirror polishing.

This product is suitable for automobile manufacturing and repair industry, construction industry, chemical light industry, ship manufacturing and repair industry, machinery manufacturing industry, furniture manufacturing, decoration and decoration industry, municipal engineering, and self-repair.