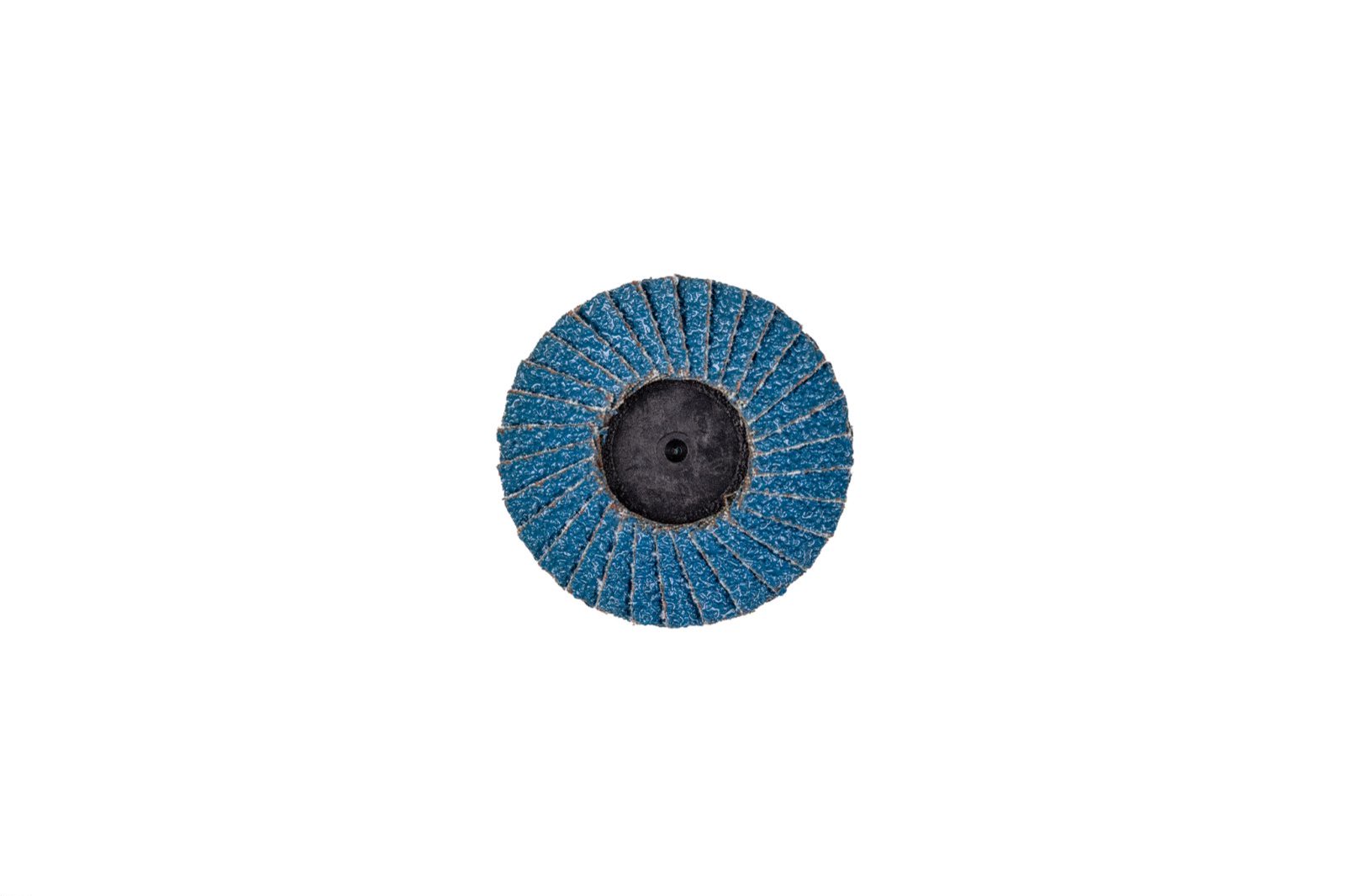

The mini Flap Disc is mainly used for grinding, polishing and slight cutting of metal or non-metal materials, and is suitable for weld treatment, wood processing and creative handicrafts in industrial production and other fields.

Main functions Removal of burrs and rust : Through the interlaced tooth pattern design, it efficiently removes rust and burrs on the metal surface and weld seams, making the surface smooth and flat.

polishing treatment : By using slats of different mesh sizes (such as 60-200 mesh), it can achieve an effect from rough grinding to mirror polishing, and is suitable for surface treatment of non-metallic materials such as stone and wood.

cutting operation : Some slats (such as 60 mesh) can cut hard materials like tiles and wood, and their efficiency is higher than that of traditional tools.

Typical application scenarios industrial field : used for weld grinding and surface finishing of metal parts in automobile manufacturing and ship maintenance.

carpentry and decoration : Dealing with burrs on wood boards and sanding marble countertops, the efficiency is more than five times higher than that of traditional sandpaper.

High grinding flexibility: The multi-layer flap structure of the polyester fiber flap disc, broussonetia papyrifera, provides excellent elasticity and compliance, enabling it to easily adapt to various curved, arched, and uneven workpiece surfaces for all-around, dead-angle-free grinding, making it particularly suitable for processing complex-shaped workpieces.

Fine grinding results: Due to the uniform flap distribution and diverse abrasive grain sizes, the polyester fiber flap disc can perform precise surface treatment during grinding, effectively reducing scratches and defects. The processed surface becomes smooth and flat with high glossiness, making it ideal for polishing and other precision machining processes.

Excellent heat dissipation and chip removal: The gaps between the flaps provide channels for heat dissipation and chip removal, allowing timely expulsion of heat and debris generated during grinding. This prevents heat buildup that could cause workpiece surface burns or clogging of the abrasive cloth, ensuring stable grinding progress and extending the service life of the disc.

Wide applicability: Whether for rust removal and deburring of metal materials, sanding and polishing of wood, or surface treatment of plastic parts, the polyester fiber flap disc performs effectively, meeting diverse grinding needs across different industries and materials.

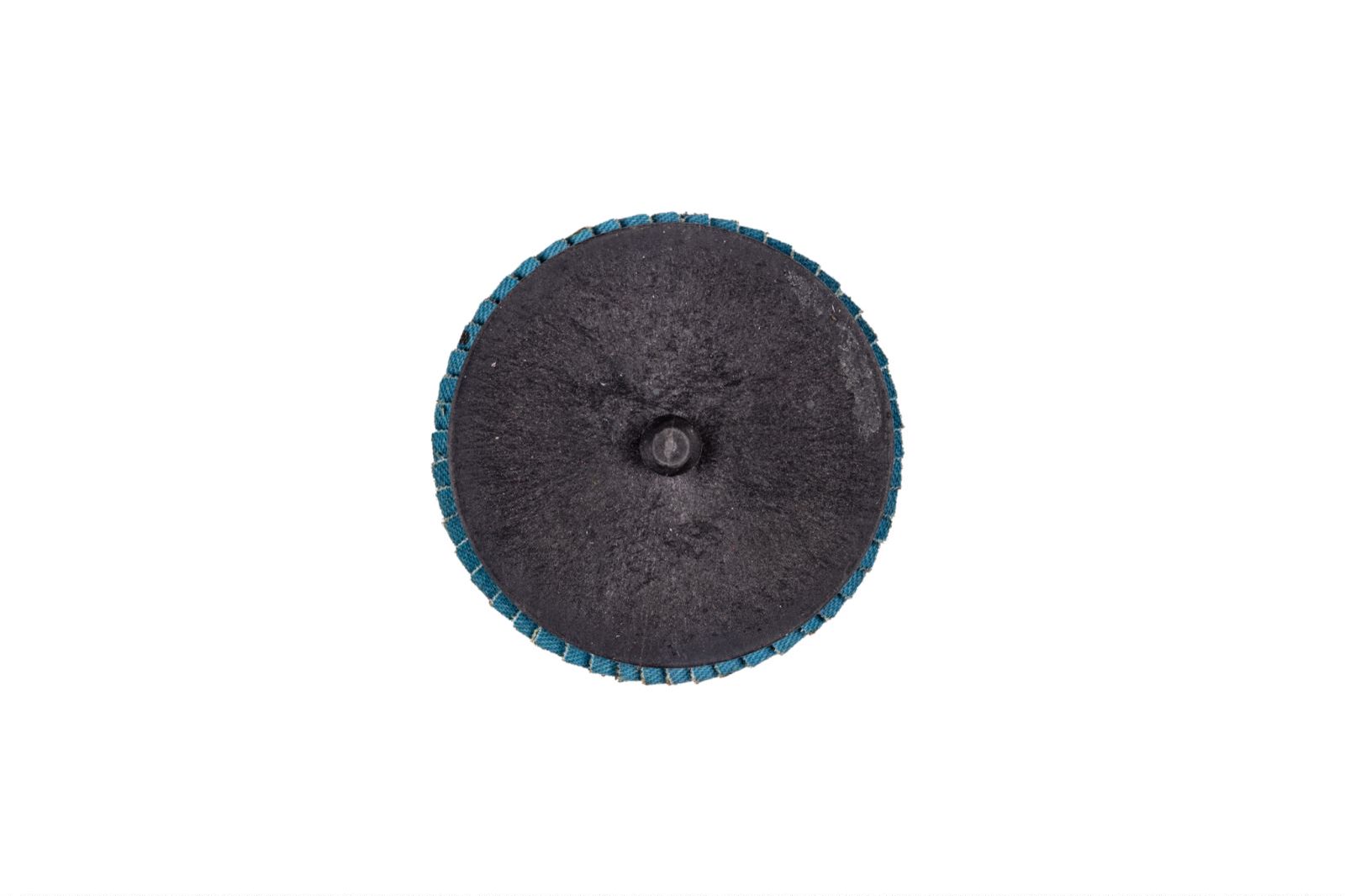

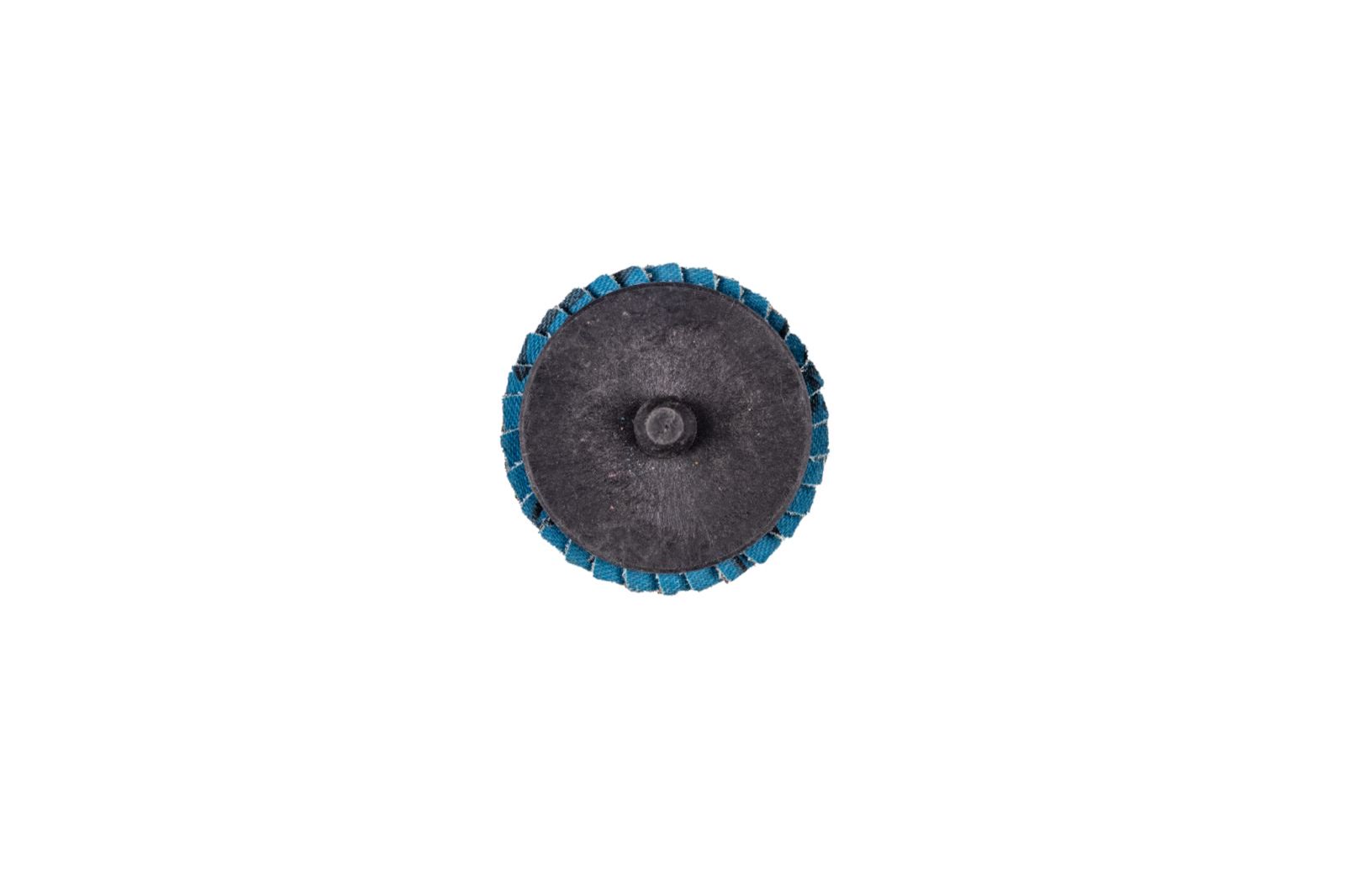

Easy replacement: The polyester fiber flap disc features a simple connection method with grinding equipment, typically fixed via a central hub that mates with the equipment spindle. The replacement process is quick and convenient, effectively reducing equipment downtime and improving work efficiency.