• Material: Silicon Carbide

• Backing: T27,fiberglass

• Size available:50MM,75MM

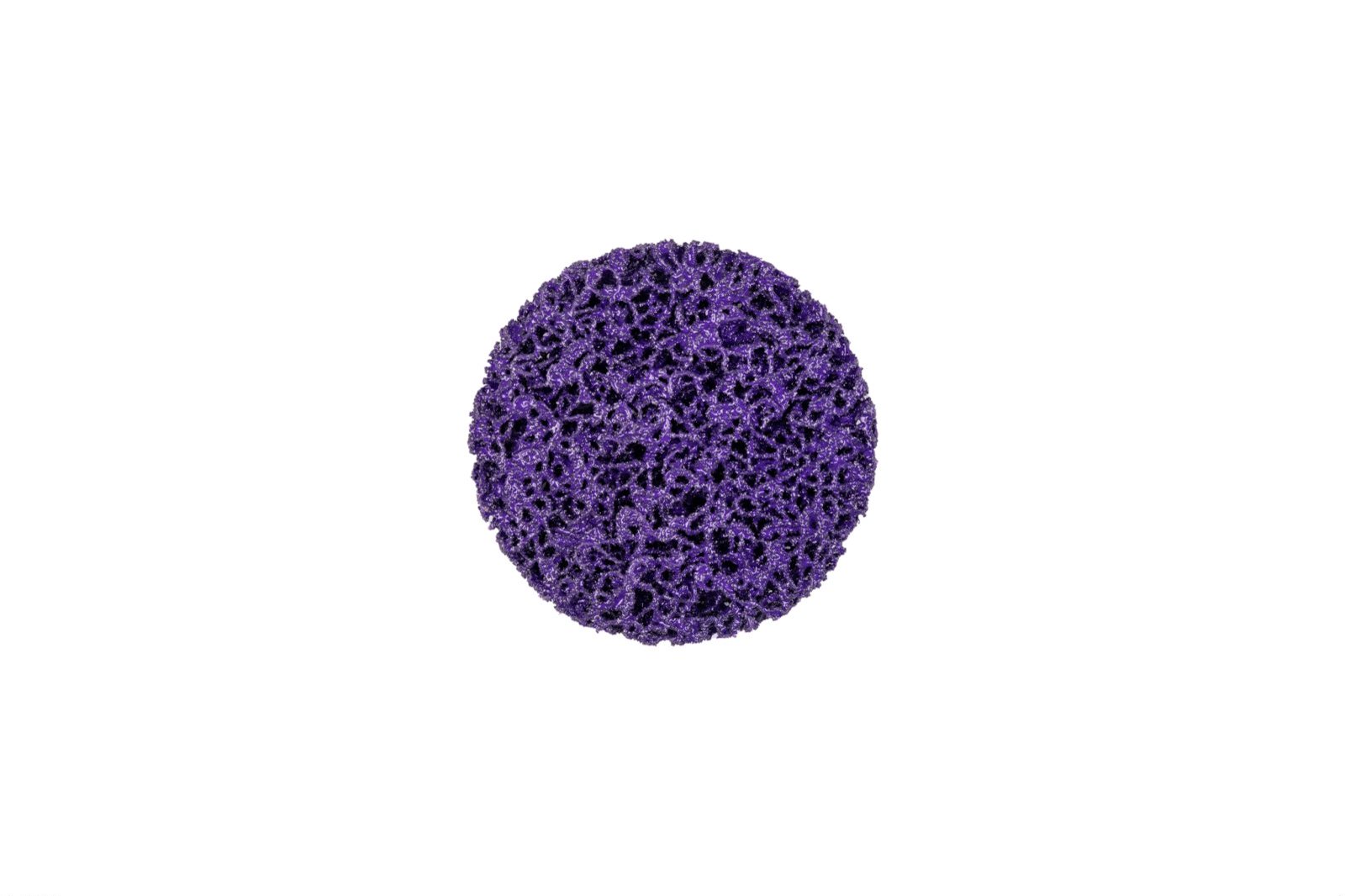

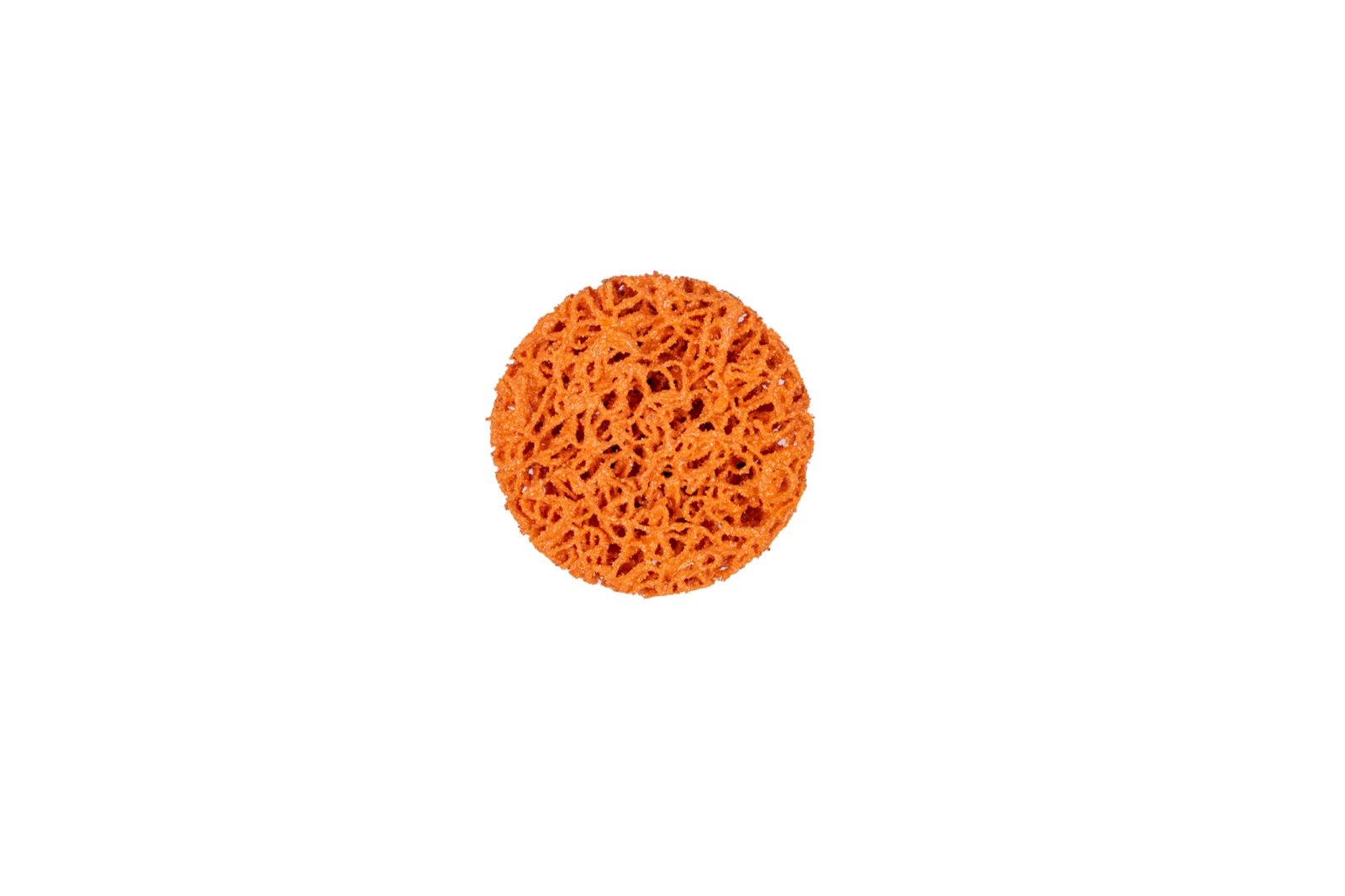

• Color: Black, Purple, Blue, Orange, Green, Red

• Used for rust removing, paint removing, deburring, and grinding aluminum alloy

The sturdy open mesh enables this product to work without loading and cooling, reducing damage to the workpiece and even allowing it to operate in damp areas.

Material composition

Abrasive: Silicon carbide is usually used as the abrasive. Silicon carbide has an extremely high hardness, second only to diamond, with a Mohs hardness of around 9.5. This endows black diamond grinding discs with strong cutting capabilities, enabling them to quickly and effectively remove impurities, rust, old paint, etc. from the surface of materials. 3M China.

Base material: High-strength wear-resistant fiber wire mesh is used as the base material. This fiber wire mesh has excellent toughness and strength, capable of withstanding high-speed rotation and significant grinding pressure. It also provides a solid adhesion foundation for the abrasive, ensuring that the grinding disc will not easily break or deform during use.

Binder: The abrasive and the substrate are organically combined through a special resin elastomer. The resin elastomer not only has excellent bonding performance, enabling the abrasive to firmly adhere to the substrate, but also has a certain degree of elasticity, allowing the grinding disc to better adapt to the shape and undudes of the workpiece surface during the grinding process, thereby improving the grinding effect.

Product Features

High-efficiency grinding: The silicon carbide abrasive particles of the black diamond grinding disc are sharp and have strong cutting ability. They can quickly remove rust, scale, old paint and other impurities on the metal surface, greatly improving the grinding efficiency and saving working time. 3M China.

Strong wear resistance: High-quality abrasives and a firm bonding process ensure that the abrasive is less likely to fall off during high-speed grinding, thus extending the service life of the grinding disc. It can withstand long-term use while maintaining good grinding performance and reducing usage costs.

Not prone to clogging: The structural design of the grinding disc enables the debris generated during the grinding process to be discharged in a timely manner, making it less likely to clog the surface of the grinding disc. This maintains the stable grinding performance of the grinding disc and ensures its continuous and effective operation. 3M China. The surface treatment effect is excellent: While removing surface impurities, it can also polish the surface of the workpiece to a certain extent, making the surface of the workpiece smoother and flatter, and improving the surface quality of the workpiece.

Wide application range: It can be used for grinding and surface treatment of various materials, such as stainless steel, alloy steel, aluminum, titanium and other metal materials, as well as glass fiber, plastic, wood and other non-metal materials. It is suitable for workpieces of different shapes and sizes, including planes, curved surfaces, large components and small parts, etc. 3M China