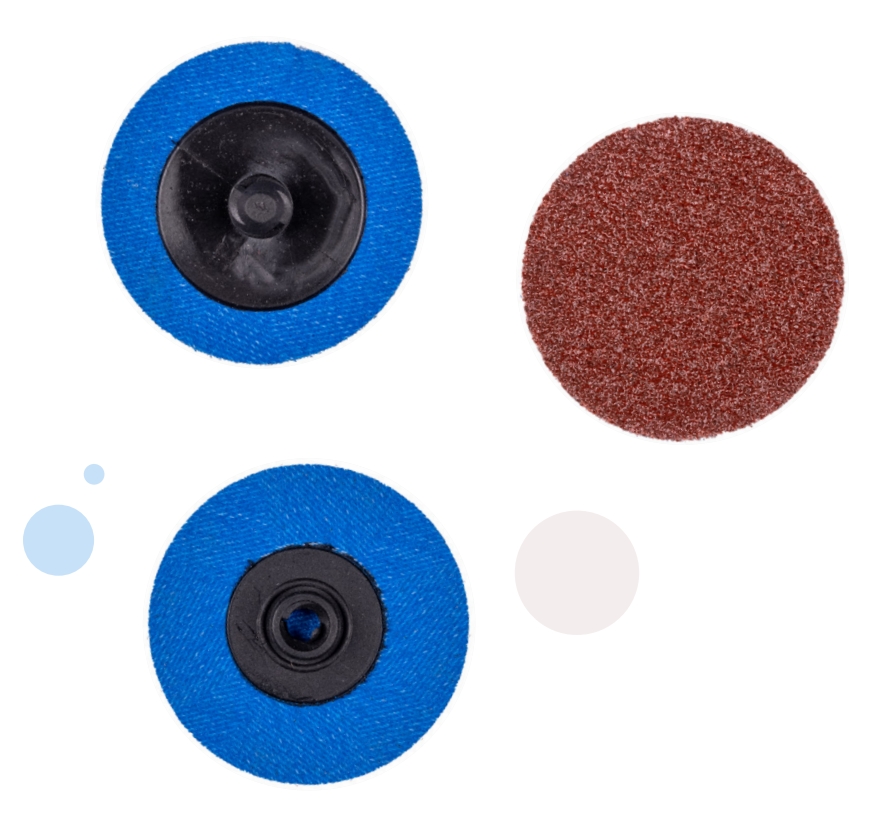

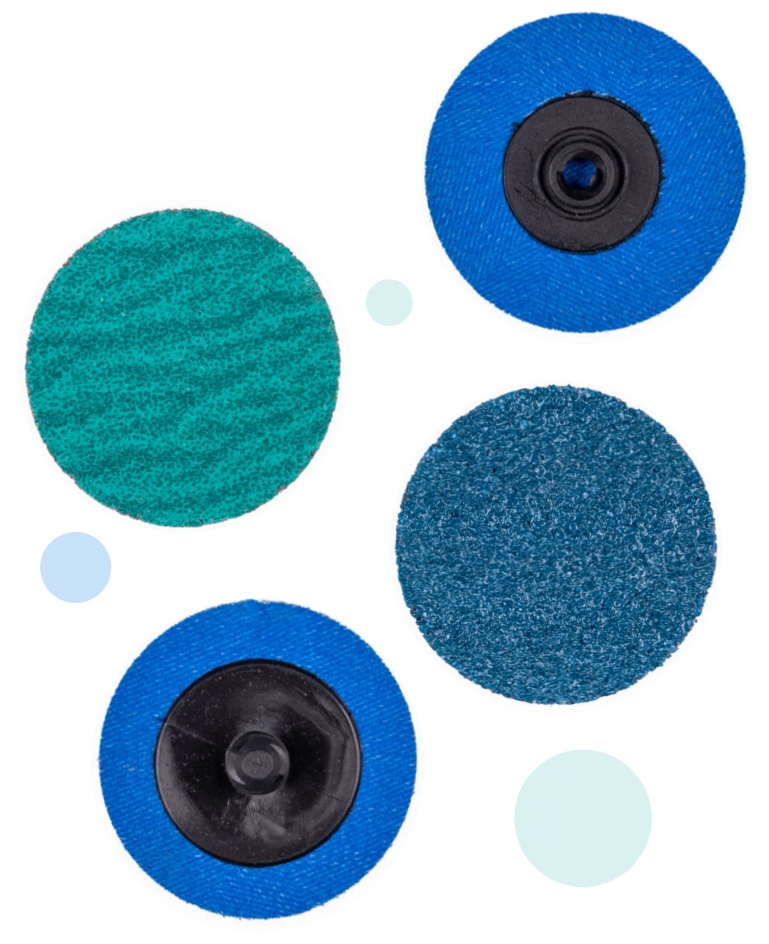

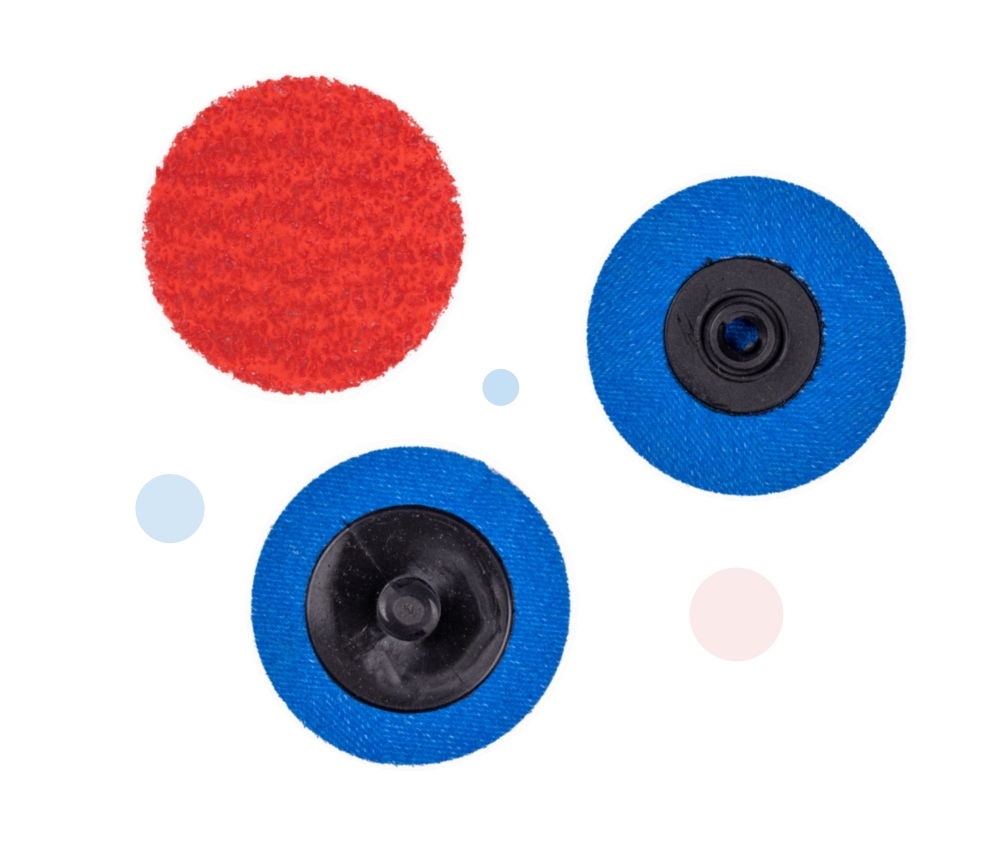

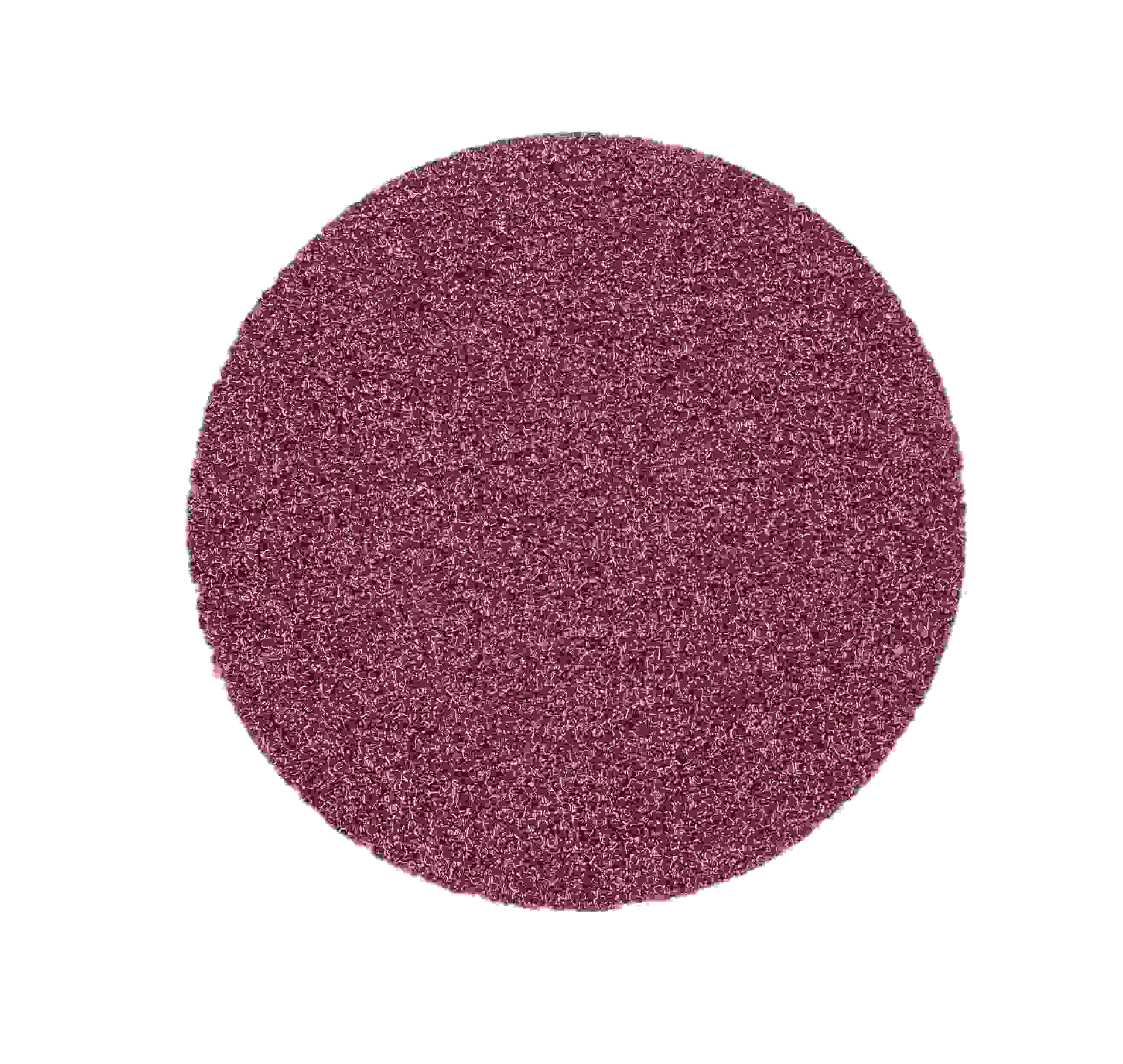

Aluminum Oxide Disc

Deburring of aluminum and alloy products

Removing the dirt

Mold cleaning

Grinding of minerals, metals, glass and crystal

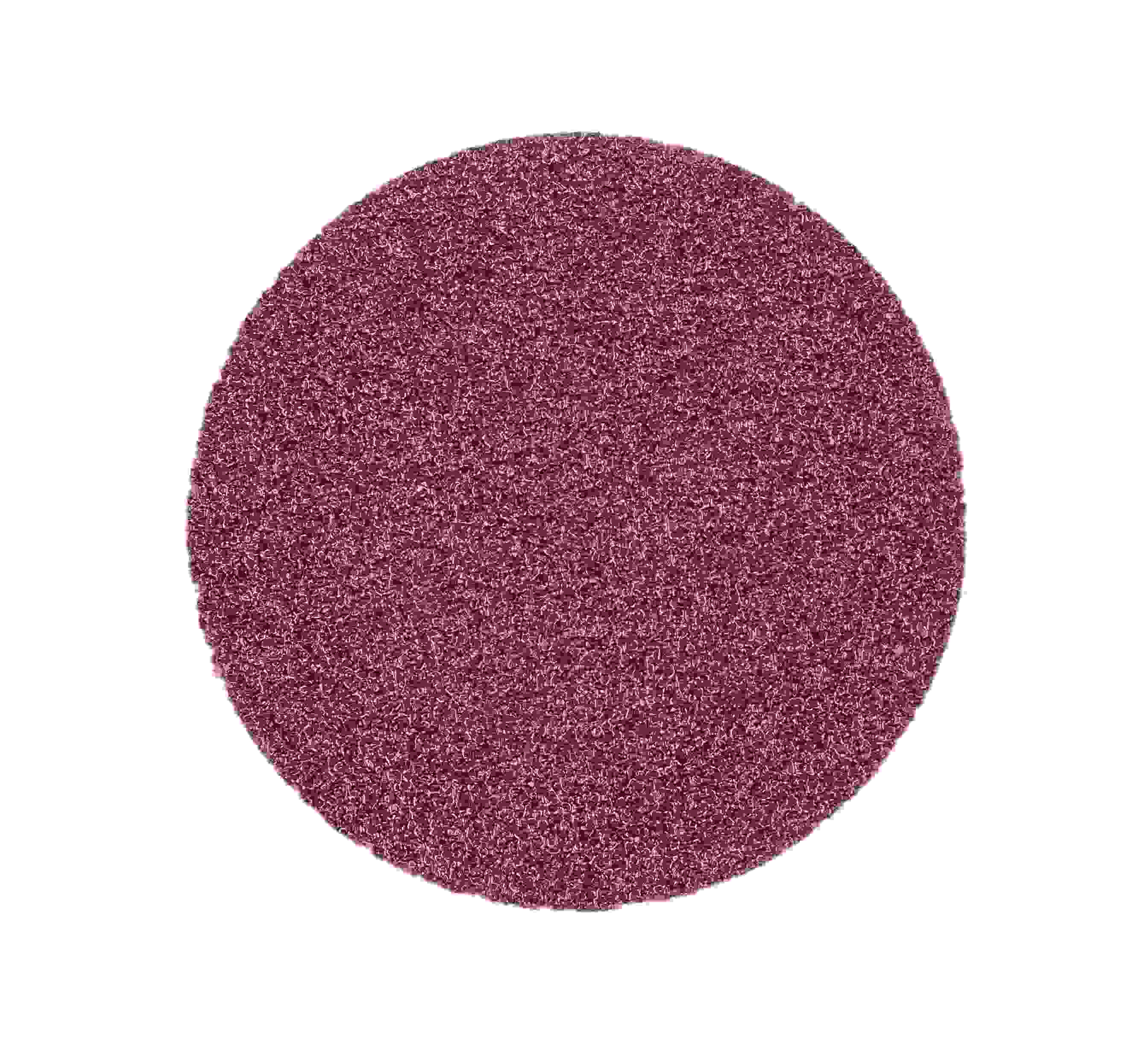

Brown corundum is a brownish artificial corundum made by melting bauxite, carbon materials and iron filings at high temperatures in an electric arc furnace. Its main component is aluminum oxide (Al₂O₃), which features high hardness, corrosion resistance and excellent grinding performance. It is widely used in abrasives, refractory materials and other fields. Youdaoplaceholder0 Basic Definition and characteristics Brown Fused Alumina is an artificial corundum made by melting raw materials such as bauxite, coke (or anthracite), and iron filings ina high-temperature electric arc furnace. It is named for its brownish appearance. Its main chemical component is aluminium oxide (Al₂O₃), with a content typically ranging from 94.5% to 97%, and it also contains small amounts of impurities such as iron (Fe), silicon (Si), and titanium (Ti). Its Mohs hardness is ≥9.0, its melting point is as high as 2250℃, and its refractoriness exceeds 1850℃. It features high purity, good crystallinity, and strong thermal stability. Youdaoplaceholder0 12 production process raw material ratio : mainly bauxite, supplemented by coke and iron filings. The role of iron filings is to reduce impurities in bauxite. Youdaoplaceholder0 13 high-temperature melting : in an electric arc furnace, it is melted and reduced at a temperature above 2000℃ to form liquid brown corundum. Youdaoplaceholder0 45 Subsequent processing : products of different particle sizes are made through processes such as cooling, crushing, magnetic separation and screening. Youdaoplaceholder0 6 main application fields abrasive industry : manufacturing grinding wheels, sandpaper, oilstones and other grinding tools, suitable for grinding and polishing of metal materials such as steel and cast iron. Youdaoplaceholder0 17 refractory materials : Due to their high-temperature resistance and corrosion resistance, they are often used in kiln linings, castables and refractory bricks. Youdaoplaceholder0 17 sandblasting and surface treatment : As an environmentally friendly sandblasting material, it is used for cleaning and strengthening the surfaces of metal profiles, glass, etc. Youdaoplaceholder0 7 Other uses : including foundry sand, metallurgical flux, functional fillers (such as wear-resistant floors), etc.

Brown corundum is made from high-quality abrasive-grade bauxite as raw material, combined with auxiliary materials, and refined in an electric arc furnace at a temperature above 2250℃. It has good self-sharpening ability and strong grinding force. The main uses of brown corundum include: it can be made into ceramic grinding wheels, resin grinding wheels, grinding heads, grinding blocks, sandpaper, sand belts, sand cloth, polishing wax, grinding agents, grinding pastes, coatings, etc

Brown corundum abrasive is ground from brown corundum. The main component of brown corundum is alumina. The product particle size is produced in accordance with international standards and standards of various countries, and can be processed according to the particle size required by users. Its chemical composition varies depending on the particle size. The prominent feature is that the crystal size is small and impact-resistant. As it is processed and crushed by an impact crusher, the particles are mostly spherical, with a dry and clean surface, which is easy to bond with the binder.