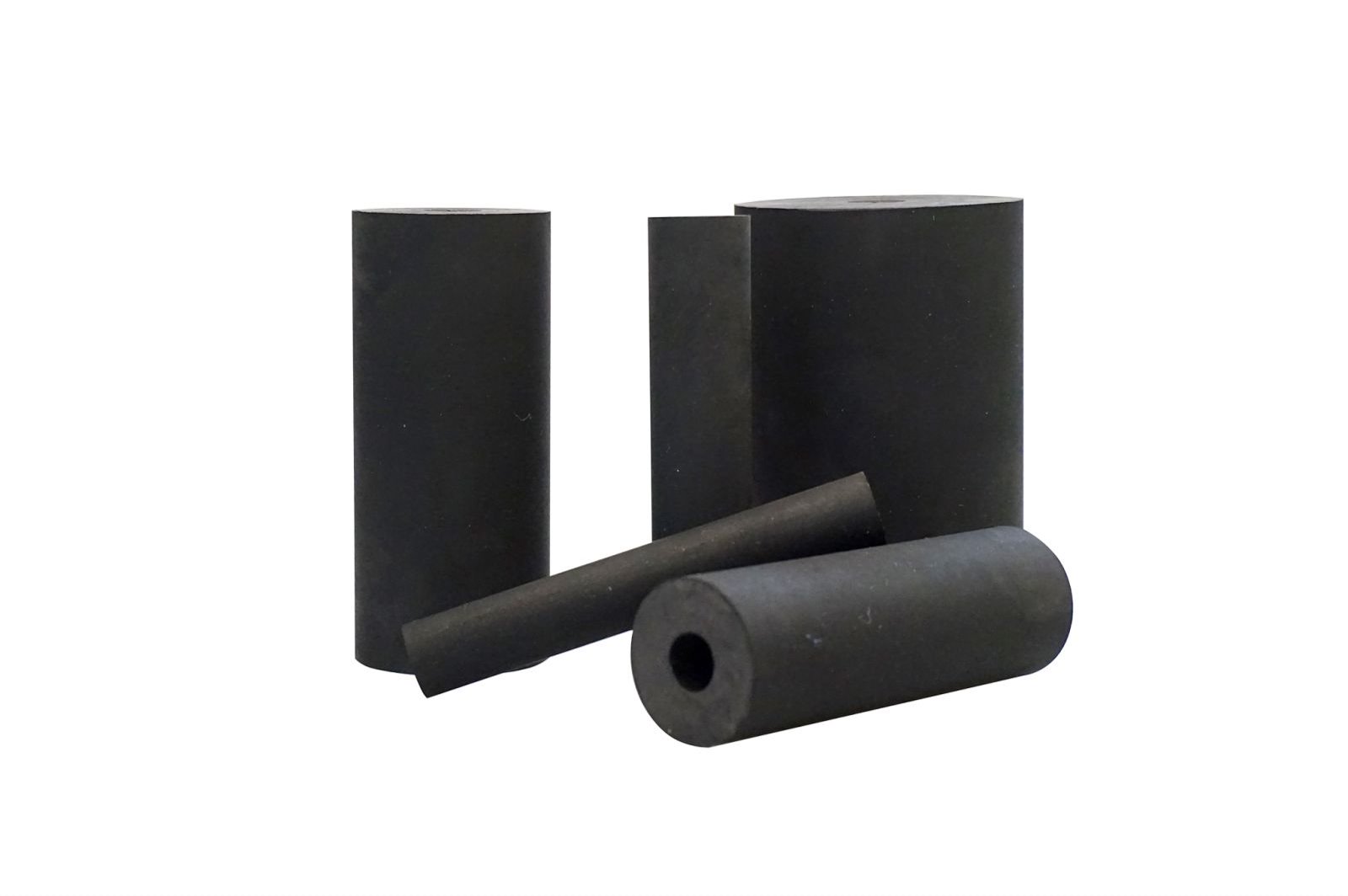

A sanding drum is a cylindrical grinding tool that plays a significant role in surface treatment for various materials such as metals, wood, and plastics, thanks to its unique broussonetia papyrifera structure and high-quality abrasives. It efficiently performs tasks like sanding, rust removal, deburring, and polishing, adapting to the processing needs of workpieces with different shapes. Particularly excelling in handling complex areas such as curved surfaces and grooves, it is a commonly used grinding tool in industrial production, furniture manufacturing, automotive repair, and other fields.

Core Materials: The abrasive types of sanding drums are diverse, commonly including brown fused alumina, white fused alumina, and silicon carbide. Brown fused alumina abrasives feature high hardness and good toughness, making them suitable for grinding metal materials. White fused alumina abrasives exhibit high purity and excellent grinding precision, ideal for processing requiring superior surface quality. Silicon carbide abrasives possess extreme hardness and strong wear resistance, often used for grinding non-metallic materials such as stone and ceramics.

The bonding agent typically employs resin or glue, which firmly adheres the abrasives to the substrate surface, ensuring minimal abrasive shedding during grinding and guaranteeing the sanding drum’s stable performance and service life. The substrate is mostly made of paper, cloth, or fiber materials. Paper-based substrates are cost-effective and suitable for light grinding; cloth-based substrates offer good toughness and high strength, making them applicable for heavier grinding tasks; fiber-based substrates combine strength and elasticity, better adapting to complex surface processing.

Structure of Broussonetia Papyrifera Features: The sanding drum is cylindrical in structure, composed of a substrate and an abrasive layer. The abrasives are uniformly distributed on the outer surface of the substrate, forming a hard grinding layer. Both ends of the substrate usually feature mounting components for connection to corresponding grinding equipment, such as sanders or angle grinders. This Broussonetia papyrifera structure enables the sanding drum to achieve grinding effects through friction between the abrasive layer and the workpiece surface during high-speed rotation. Moreover, its cylindrical shape ensures excellent conformity to curved surfaces and grooves.

• Premium Aluminum Oxide Grain

• Excellent for removing parting lines, imperfections, and burrs on all surfaces

• Great in curved, corner, contoured, and hard to reach areas

• Used in ferrous and non-ferrous metals,Stainless steel, high tensile steel, wood