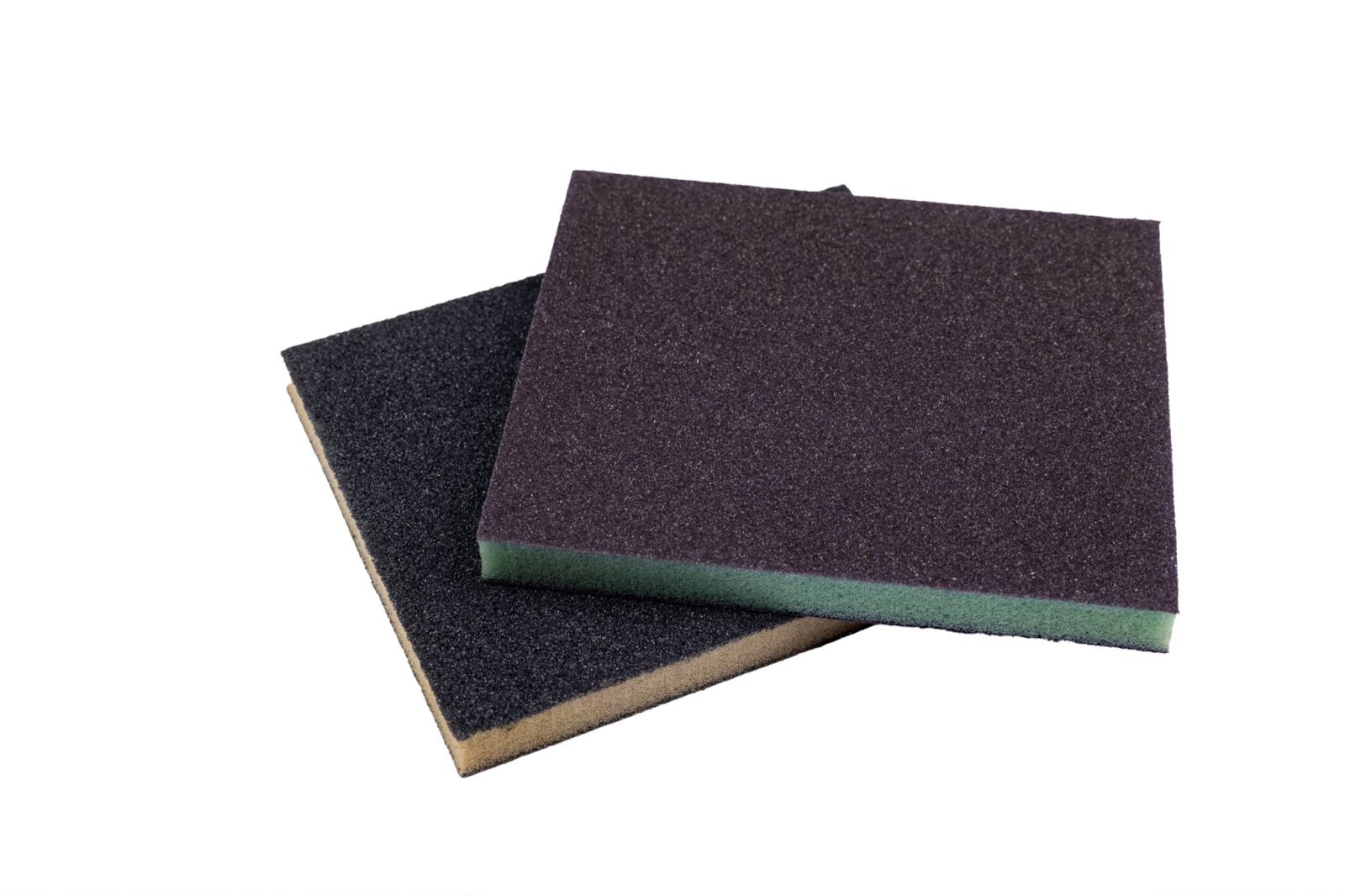

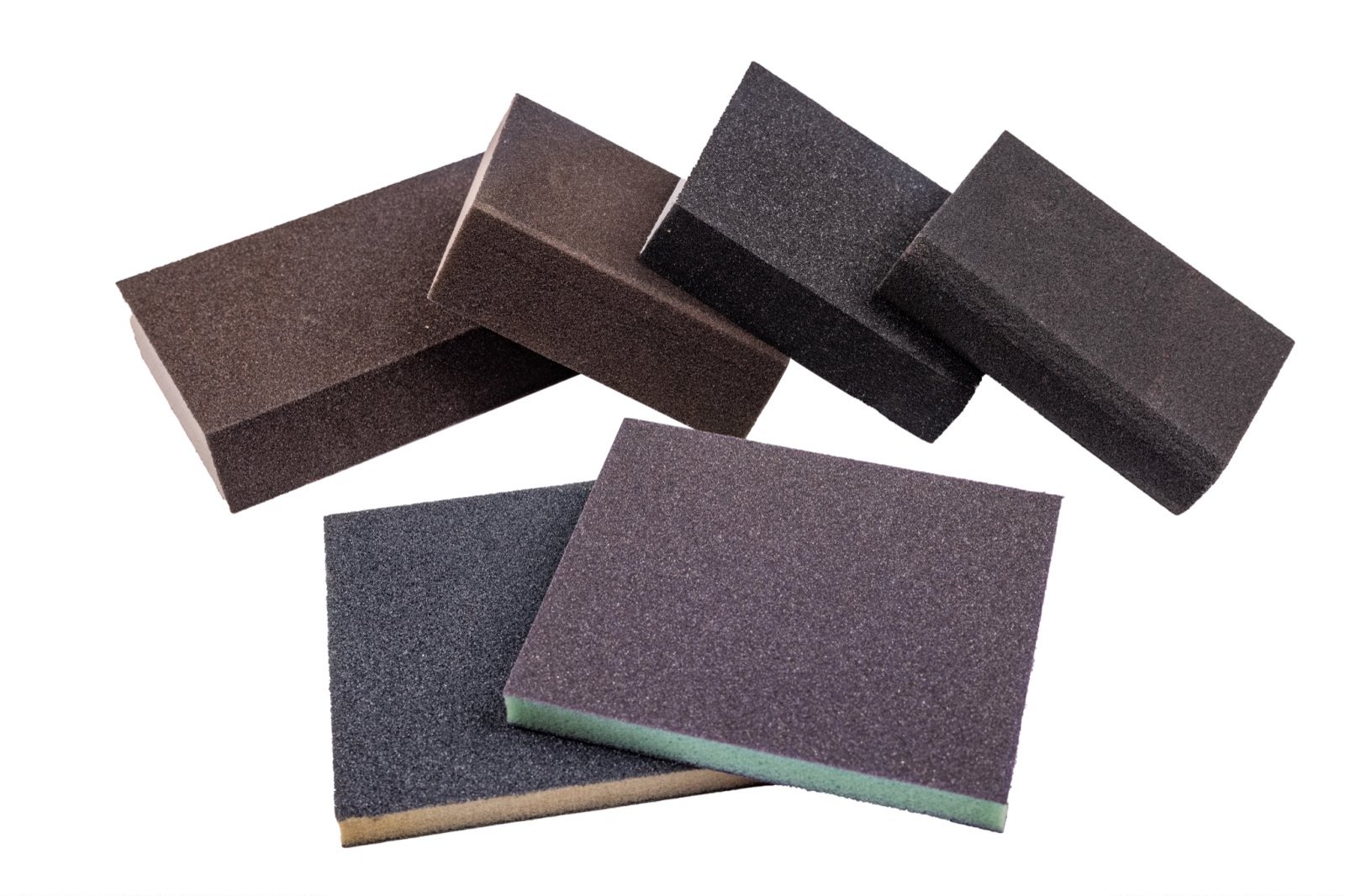

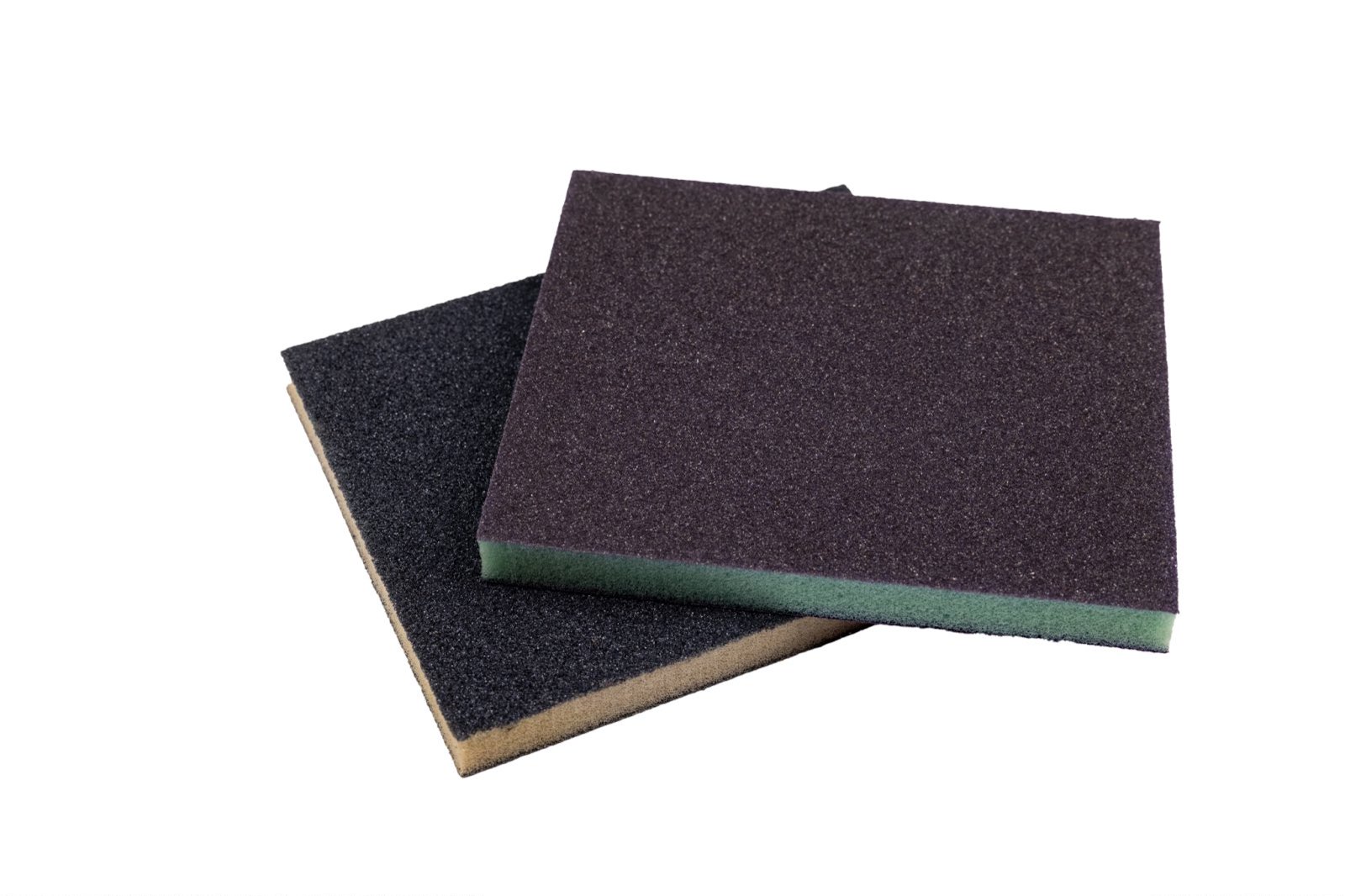

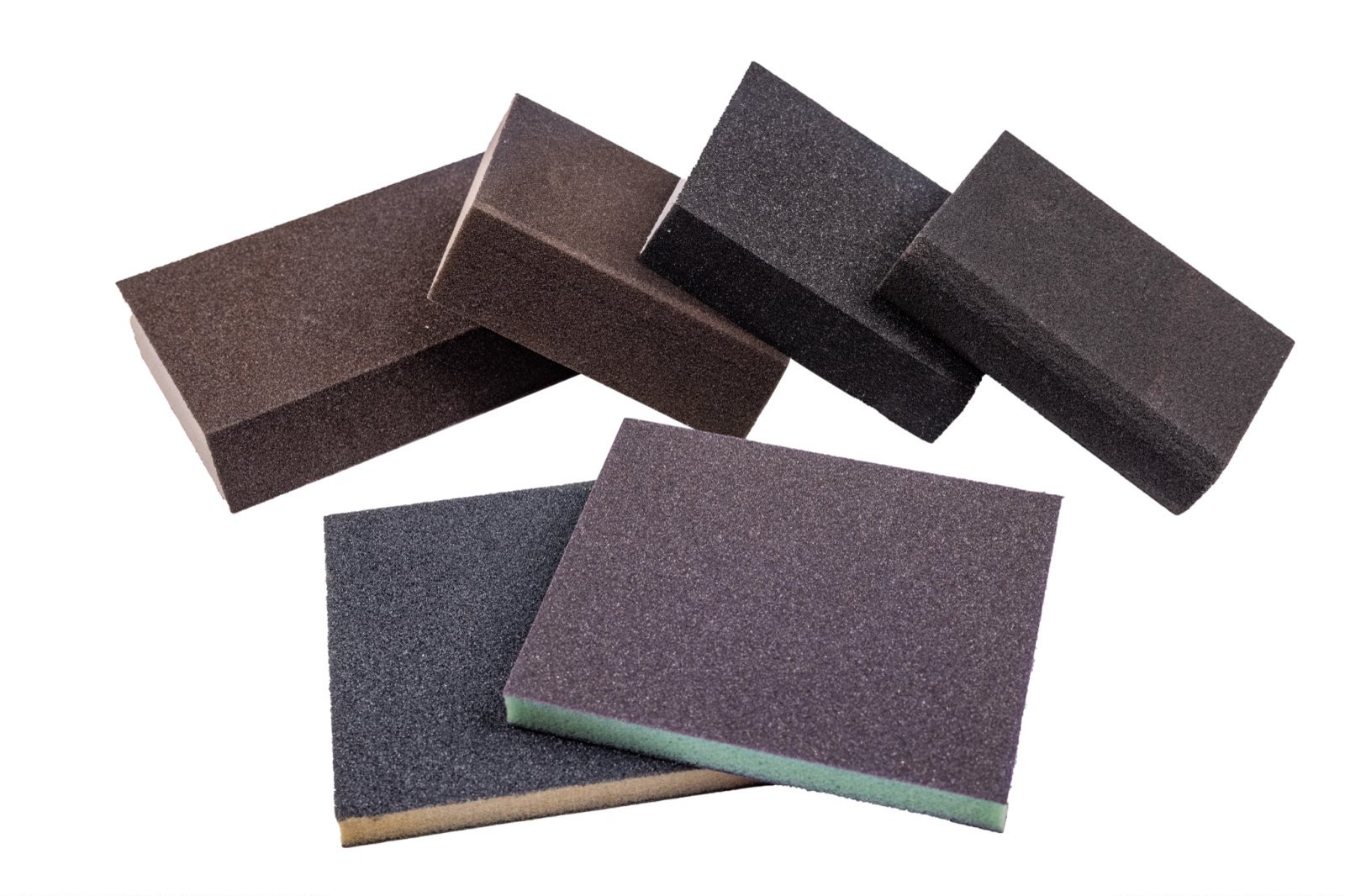

• Premium abrasive grain on a soft, foam backing

• Foam backing provides ultimate conformability and is washable for long life

• For use on wood moldings, metal contours, drywall sanding,and paint removal applications, hardwoods and softwoods, plastic, paint,fiberglass, auto body filler, and drywall compounds, Ferrous and non-ferrous metals.

•Material:aluminum oxide,silicon carbide with low density,middle density,high density foam,EVA

Primarily consists of a sponge matrix and abrasive grit. The sponge matrix provides elasticity and flexibility, with common densities including low, medium, high, and ultra-high. The abrasive grit is key to achieving grinding and polishing functions, with commonly used abrasives such as aluminum oxide and silicon carbide.

Product Features: Characterized by softness, excellent elasticity, and strong flexibility, it conforms well to irregular or complex workpiece surfaces without scratching during grinding. Additionally, it exhibits good water resistance and acid/alkali resistance, suitable for both dry and wet grinding methods. It is easy to clean, reusable, and has a long service life.

Production Process: Typically involves adhesive application, flocking, lamination, and die-cutting. First, the sponge matrix is treated to ensure good surface adhesion. Then, abrasive grit is evenly attached to the sponge surface via flocking technology. Subsequent lamination processes reinforce the bond between the abrasive and matrix. Finally, the product is die-cut into various shapes and specifications based on different application needs.

Application Fields

Furniture Manufacturing: Suitable for manual furniture sanding, capable of polishing and deburring solid wood furniture surfaces to achieve a smoother and finer finish. It can also be used to treat edges, curves, and other intricate parts of furniture, enhancing overall quality and aesthetic appeal.

Automotive Repair: During automotive paint touch-ups, it can be employed to sand the repaired areas, ensuring a seamless transition with the surrounding paint. Additionally, it can remove rust spots and polish metal components, restoring the vehicle’s surface to a pristine condition.

Plastic Product Processing: Effective in sanding out scratches and burrs on plastic product surfaces, resulting in a smoother finish and improved visual quality. It is also suitable for contour sanding and polishing of plastic products, meeting diverse processing requirements.

Metalworking: Applicable for surface sanding of various metal products, such as stainless steel and aluminum alloys, including rust removal, descaling, and polishing. This ensures the metal surface achieves the desired roughness and smoothness.

Decorative Craft Production: Highly suitable for surface treatment of decorative crafts, such as polishing and buffing ceramic, glass, wooden products, and other handicrafts, effectively enhancing the texture and artistic value of the artworks.